The size, design, finished appearance and purpose of the ferrous item will determine which solution will provide the best surface finish. Please consult the CP Plating team with your requirements. We also encourage customers to supply sample quantities and design drawings for critical parts to obtain the best results.

The zinc plated layer is then coated in a passivate (chromate) solution giving the article either a silver/clear or gold/yellow appearance. The secondary layer of passivate solution adds a layer of protection by delaying the oxidation (corrosion) of the primary zinc layer. CP Plating has integrated trivalent chrome (Cr III+) passivate solutions into our production lines to meet the automotive industries environmental demand for ‘hexavalent chrome (Cr VI+) free’ metal finishes. CP Plating underwent the significant changes required to deliver trivalent passivates back in 2008 and works closely with our automotive customers to ensure OEM quality standards are being met.

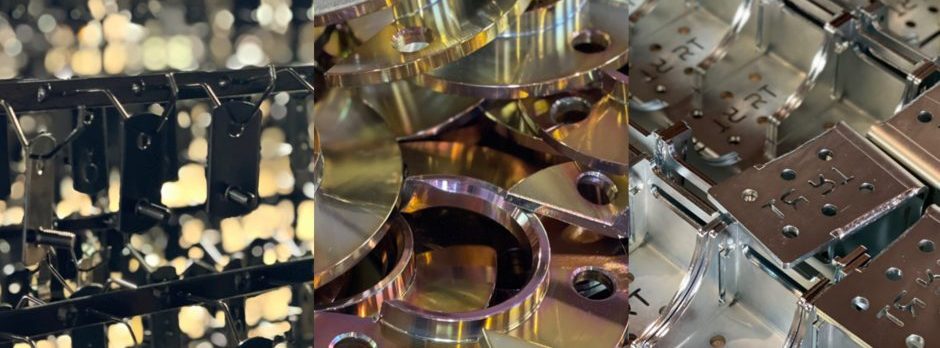

There are three main zinc electroplating lines at our Eagle Farm facility. Our main (Still) line is a rack type system operating with dual 500 kg chain hoist, handling product up to 6.1m long, 1.4m deep and 0.45m wide. Both zinc chloride and alkaline zinc based plating solutions are available on the Still Line with the silver/clear or gold/yellow passivate finish. The 6.1m tank length gives us the largest zinc electroplating capacity in Queensland and allows for standard lengths of hydraulic tube to be plated easily.

The Auto Line is an automatic ‘rack-n-return’ alkaline zinc process, strictly focused on high volume automotive and stamped sheet metal parts. Items are currently finished in a silver/clear, trivalent chrome passivate only. Once the system if fully loaded it processes one rack in less than 3 minutes!

Our most recent acquisition is the automatic Barrel Line plating with a zinc chloride solution. Finishes are currently supplied in either silver/clear or gold/yellow passivate before the items are spin dried and stored for customer pick-up. Once the Line is fully loaded it will produce a barrel plated work approximately every 10 minutes.

Neutral Salt Spray (NSS) Testing Standard: ASTM B117-09