Zinc electroplating, or as sometimes referred to as electrogalvanizing, is a reliable and efficient method of corrosion protection for ferrous items exposed in light to moderate atmospheric and operational conditions. As a metal finish, zinc plating is highly important to the steel manufacturing and fabrication industries as one of the most cost effective intermediate or final finishes prior to sale.

Traditionally zinc plating has its markets in the automotive parts, sheet metal parts, hydraulic tube/fittings and fastener industries. The agricultural equipment industry has also long taken advantage of zinc electroplating as the level of corrosion protection is usually adequate for the dry regional areas in western Queensland and New South Wales.

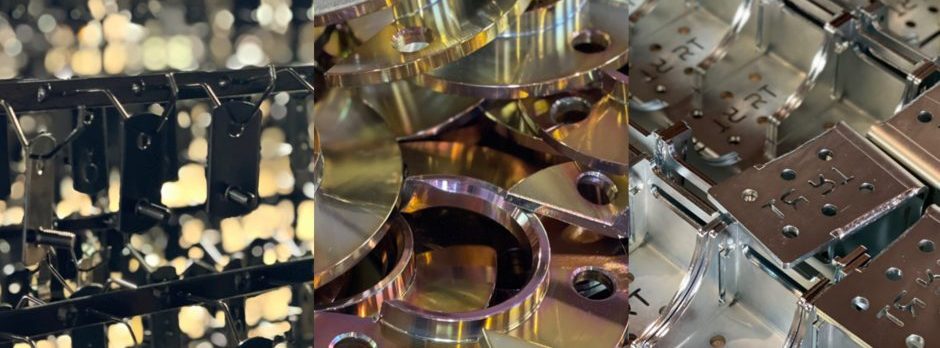

More recently we have seen light engineering and fabrication workshops specifying zinc plating as a quick, simple, cost effective means of basic corrosion protection and for visual appeal. Oil and gas customers are also using zinc plating for corrosion protection, but also as a means of presentation. Quite often large quantities of pipe, tube and fittings are stored in racks outside on a customers site. Nobody wants to drive past a few $100k worth of newly purchased stock already rusting just because its had a thread turned on the end, let alone spending downtime cleaning rusting threads instead of connecting pipe.