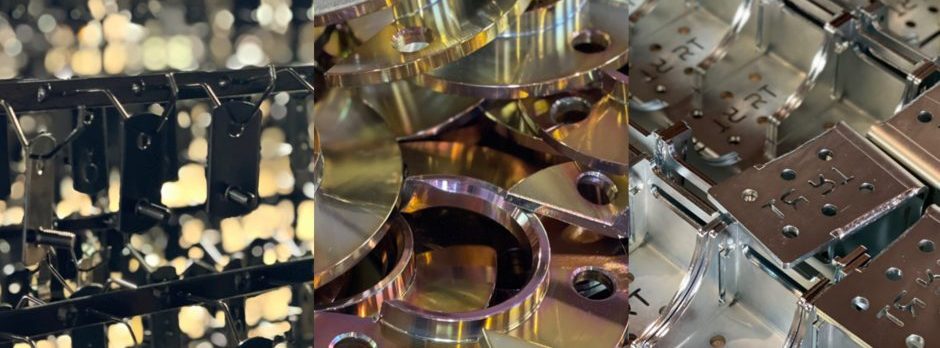

We are in the process of production trials for our new dip-spin paint application process here at CP Plating. The dip-spin (i) process will allow us to utilize chromate-free (nc) zinc flake (flZn) thin film technology coatings for a range of articles up to approximately 150x25x25mm in size, including blinds, hollows and threaded fasteners. The risk of hydrogen embrittlement for 1000MPa > high strength steel < 1800MPa can also be reduced when used in combination with mechanical cleaning methods for surface preparation. The corresponding range of specialized top coat (T1, T2, T3, & T4) systems can be used to enhance the performance of the zinc flake base coat. The top coats can also be used in combination with our current zinc electroplating and powder coating surface finishes. More to come…